Nitrogen capacity: 3-10Nm³/h

Nitrogen purity: 95%-99.9%

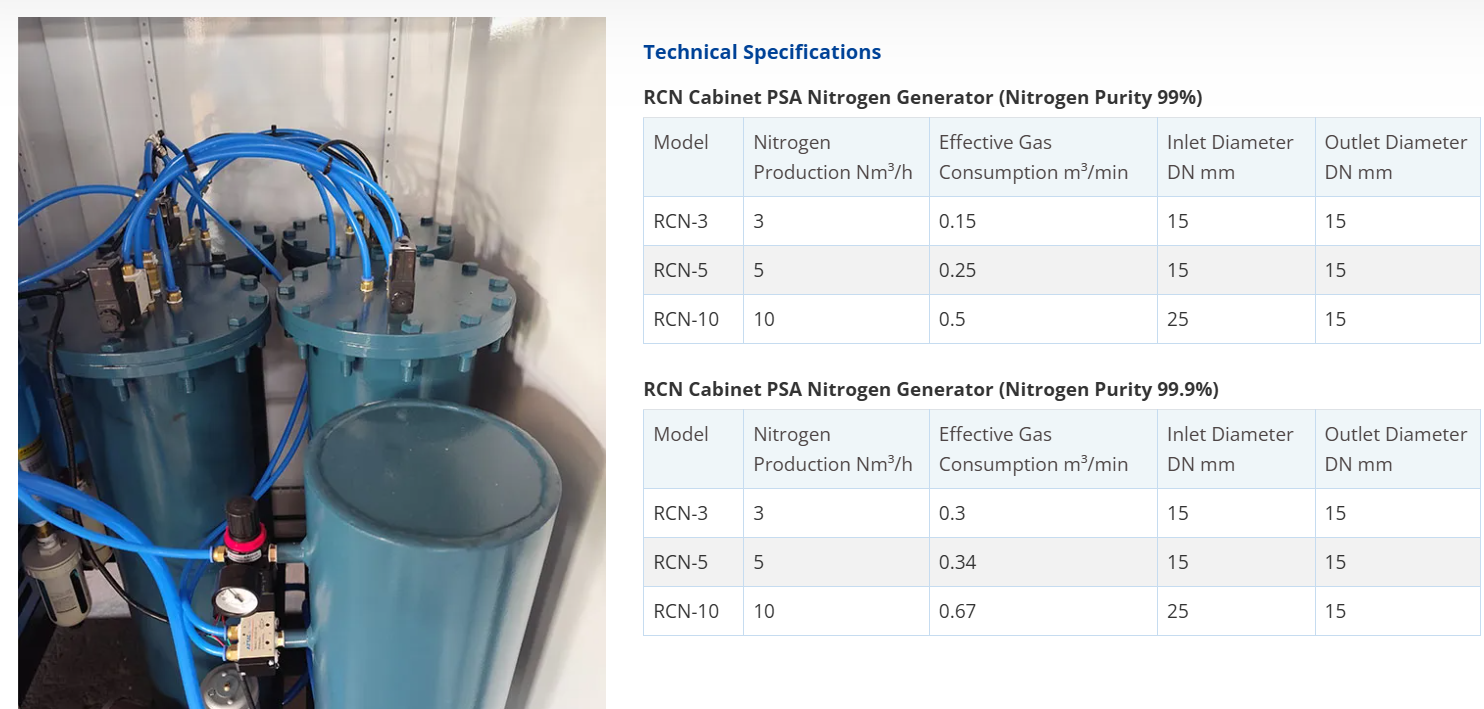

Our cabinet PSA nitrogen generator can efficiently separate nitrogen with high purity. It not only occupies small space, but also protected by a metal case, preventing damage during operation. It is suitable for low-volume nitrogen generation, such as food preservation in small food processing manufacturers, nitrogen protection in scientific laboratories, etc. Our cabinet PSA nitrogen generators are designed for meeting different requirements across various industries, detailed specification and size can be customized upon customers’ request.

Cabinet PSA Nitrogen Generator

Nitrogen capacity: 3-10Nm³/h

Nitrogen purity: 95%-99.9%

Our cabinet PSA nitrogen generator can efficiently separate nitrogen with high purity. It not only occupies small space, but also protected by a metal case, preventing damage during operation. It is suitable for low-volume nitrogen generation, such as food preservation in small food processing manufacturers, nitrogen protection in scientific laboratories, etc. Our cabinet PSA nitrogen generators are designed for meeting different requirements across various industries, detailed specification and size can be customized upon customers’ request.

Features

Separated nitrogen is specially processed to be free of impurities and odor.

The processed air source will be extremely dry, and closed to anhydrous, low-oxygen state.

Customization Capability

This cabinet-type compact nitrogen generator can be designed to deliver nitrogen flow rates of 1-30 Nm³/h with purity ranging from 95% to 99.999%, based on diverse customer applications and working conditions. We can provide complete nitrogen system solutions, from air compressor to nitrogen storage tank, according to specific requirements.

Integration Capability

This cabinet-type nitrogen generator can be integrated for use with multiple food packaging machines or 3D printers.

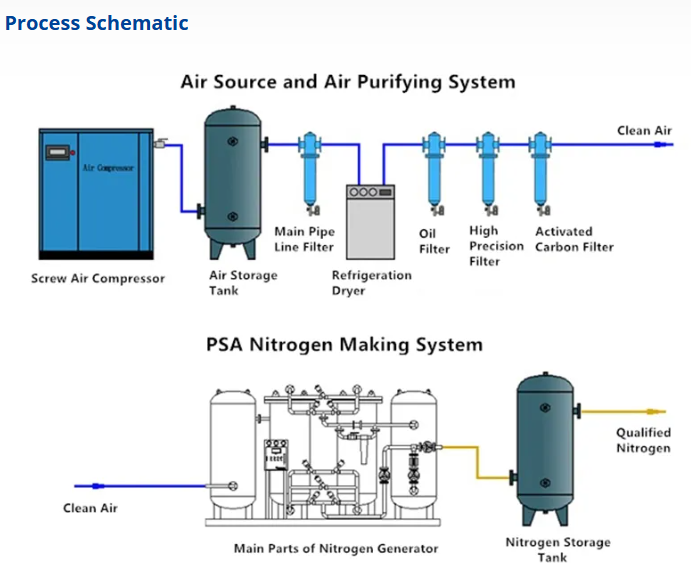

How PSA Nitrogen Generation Works

PSA nitrogen generation is a technology to separate nitrogen from air by the adsorption ability of carbon molecular sieve under pressure by air compressor. After the air is compressed and purified (removing the oil, water and dust, etc.) before transferring into the absorption tower filled with carbon molecular sieves (CMS), the oxygen molecule will be adsorbed by carbon molecular sieve, while nitrogen molecules are too large so that they will be remained in the air. Those nitrogen molecules will pass through the tower into the nitrogen buffer tank, while oxygen molecules remain in the CMS. The adsorption process is performed at certain pressure, after that the atmospheric pressure will be resumed, and the adsorbed oxygen molecules will be escaped from CMS, pass the bottom of the tower through the exhaust silencing muffler into the air, and the CMS is available to be reused. Usually PSA nitrogen generator adopts double adsorption towers in parallel, they will be used alternatively for the adsorption and collection of the nitrogen under different pressure, continuously supporting the separation of oxygen and nitrogen. The above process will be automatically controlled by PLC system.

Contact: Mrs.Ho

Phone: 15397188550

E-mail: info@hzyuanda.com

Whatsapp:

Add: No. 120 Huayuan Street, Jinhua City, Zhejiang Province,China